Oxygen‑free copper, often called OFC or OFHC, refers to highly purified, electrolytically refined copper with extremely low oxygen content (≤ 0.001–0.003%). This type of copper achieves 99.95–99.99% purity and offers superior electrical and thermal performance, which making it essential in high-end electrical, vacuum, and aerospace applications.

Common Oxygen-free Copper Grades

C10200: 99.95% copper, ≤0.001% oxygen, applied for general-purpose high-conductivity uses such as electrical components, audio cables, plumbing

C10100: 99.99% copper, certified oxygen-free, applied for high-end, sensitive uses such as aerospace, vacuum environments, medical imaging equipment

OFC vs. ETP Copper

C10200/C10100 oxygen-free copper: Purity ≥ 99.95%, oxygen ≤ 0.001%, conductivity ≥ 100% IACS

C10100 OFE: Ultra-pure, 99.99% copper and oxygen ≤ 0.0005%, conductivity up to 101% IACS

C11000 ETP: Standard copper with higher oxygen (~0.02–0.04%), conductivity ~100–101% IACS [1]

Key Features of Oxygen‑Free Copper

Enhanced Conductivity & Signal Integrity

Lower oxygen and impurity levels minimize scattering of electrons, boosting both electrical and thermal conductivity—ideal for precision electronics, high-frequency circuits, and audio applications

Hydrogen Embrittlement Resistance

Oxygen-free copper avoids hydrogen-related embrittlement, ensuring material integrity during brazing, welding, or in vacuum environments

Vacuum & High-Temperature Suitability

Used in vacuum tubes, electron devices, superconductors, and aerospace components, its low gas emission and stability under 900 °C brazing enhance reliability in challenging conditions

How to Choose the Righ Oxygen‑Free Copper Product?

For high-current electrical needs, choose TU2 or C10200 bars—excellent conductivity and mechanical strength;

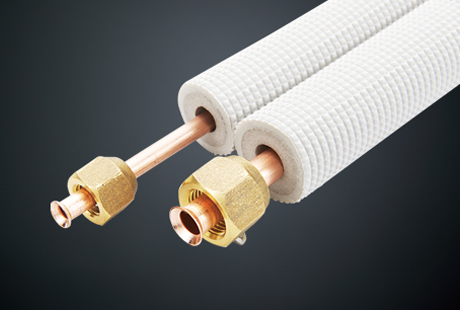

For precision tubing (medical, HVAC, electronics), select oxygen-free seamless tubes in R300–R420 grades;

For ultra-high purity and vacuum use, opt for OFE copper (C10100) tubes and bars.

Work with trusted oxygen-free copper suppliers who will provide material traceability, custom sizing options, technical support and fast delivery.

What is Driving the Oxygen-free Copper Market?

The oxygen-free copper market is experiencing steady growth due to rising demand for high-purity, high-conductivity copper materials in advanced electronics, electric vehicles, telecommunications, and renewable energy sectors.

Industries like electronics, automotive, aerospace, and audio or video systems require copper with exceptional electrical and thermal conductivity. OFC is ideal for these applications due to its ≥99.95% purity, ≤0.001% oxygen content and superior resistance to corrosion and embrittlement.

OFC is increasingly used in EV motors, battery systems, solar panels, and wind power generators for its efficiency and heat resistance. As governments push for electrification and carbon neutrality, OFC demand rises.

What's more, telecommunication cables and 5G networks require materials that reduce signal loss. OFC’s low impedance and high signal fidelity make it a preferred material for data transmission. And in the consumer electronics segment, OFC is widely used in speaker cables, headphones, and high-end audio systems for improved sound clarity and reduced distortion.

Oxygen‑free Copper Products by JINTIAN

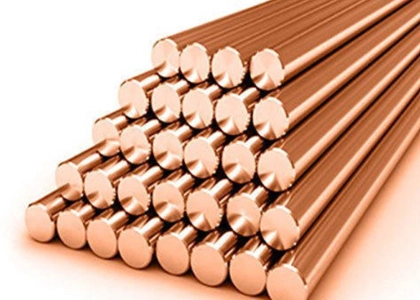

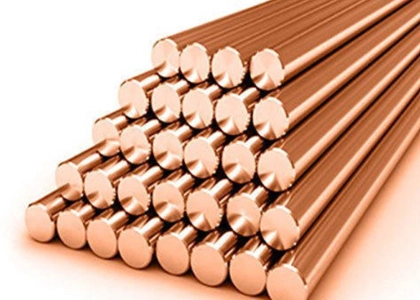

OFHC Copper Bar

Grades: T2, TU2, TU1, C10200 (CU‑OF)

Purity: ≥99.95% copper, oxygen <0.002%

Advantages: Smooth surface, precise dimensions, high conductivity, strong mechanical traits

Uses: Power transmission, electrical appliances, molds, busbars, new energy systems, subway power lines

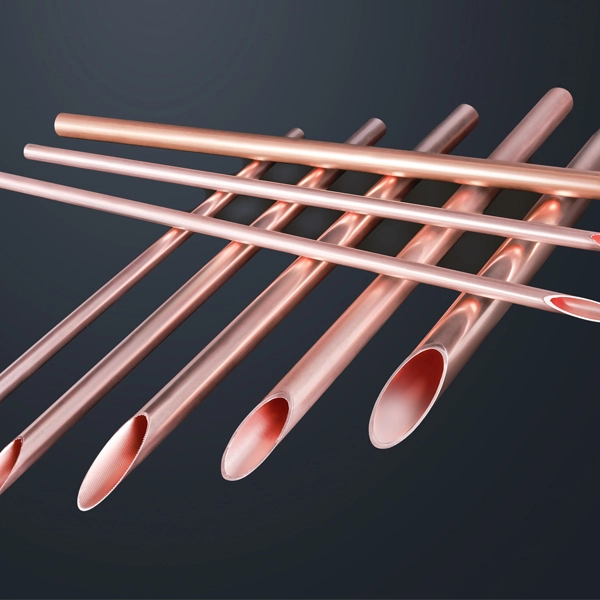

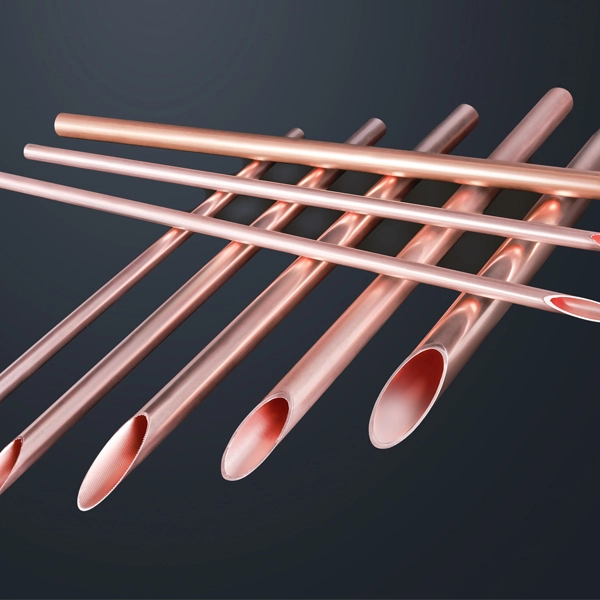

Oxygen‑free Copper Tube

Purity: ≥99.95%; oxygen-free seamless tubes

Standards: ASTM B280, JIS H3300, AS 1571, PED 4.3

Advantages: High strength (R300–R420 grades), corrosion resistance, excellent thermal/electrical performance

Uses: Power transmission, electronics, HVAC, chemical, construction industries

Contact JINTIAN Copper

As a professional copper products manufacturer, JINTIAN Copper produces high purity oxygen free copper products like oxygen-free copper pipe and oxygen-free copper bar. To learn more about our oxygen-free pure copper products:

FAQs of Oxygen‑Free Copper

Does oxygen‑free copper make a difference?

Yes, lower oxygen improves conductivity, reduces gas evolution in vacuum, and prevents hydrogen embrittlement, benefiting high-end electronic and vacuum applications.

Where is it used?

Used in busbars, vacuum tubes, superconducting magnet parts, MRI coils, high-frequency components, aerospace ducts, and advanced audio cables.

Is it better than CCA or silver‑plated copper?

OFC oxygen-free copper outperforms CCA copper-clad aluminum and silver-plated copper in conductivity, mechanical strength, and long-term stability. [2]

What is oxygen free copper wire?

Oxygen-free copper wire is manufactured from electrolytically refined copper (usually grades like C10200 or C10100) with a purity level of 99.95% to 99.99%. Unlike standard copper wire, OFC wire has virtually no oxygen, which can interfere with conductivity and durability in certain applications.

Why do cable materials prefer high-purity oxygen-free copper?

Scientific experiments have shown that high-purity oxygen-free copper enables smoother electron flow. This means that cables of the same thickness, when made with high-purity oxygen-free copper, can carry larger power while reducing energy loss. Therefore, using cables made of high-quality materials not only ensures durability and reliability but also saves energy costs.

What's the role of oxygen-free copper bars in subway systems?

Important parts of subway vehicles, such as motors, cables, and contact rails, all benefit from the superior electrical and mechanical properties of oxygen-free copper bars, ensuring the reliability and safety of train operations. Furthermore, the corrosion resistance of oxygen-free copper bars allows them to operate stably for long periods in humid and dusty subway environments.

Reference:

[1] https://en.wikipedia.org/wiki/Oxygen-free_copper

[2] https://www.gearit.com/blogs/news/copper-clad-aluminum-vs-oxygen-free-copper

English

English 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文