Designation and Standards

Standard Designation: HPb59-1 (Leaded Brass)

Implementing Standards: GB/T 5231-2012 (Wrought Brass), GB/T 4423-2007 (Bars)

International Equivalent Grades: ASTM C37700 (American Standard), JIS C3771 (Japanese Standard)

Material Category: Copper-Zinc-Lead Alloy (Cu-Zn-Pb), Copper content 57.0%-60.0%, Lead content 0.8%-1.9%, Zinc balance (approximately 38%-41%).

Product Features

Excellent Cutting Performance:

The addition of lead significantly improves machinability, making it suitable for precision turning, milling, and other automatic machine tool processing, with high surface finish.

Cutting chips break easily, improving machining efficiency, earning it the title "Free Cutting Brass".

Balanced Mechanical Properties:

Tensile strength ≥380 MPa, offering a balance of medium strength and wear resistance, but poor cold working performance (not suitable for cold heading or cold stamping).

General Corrosion Resistance:

Corrosion resistance is acceptable in dry atmosphere and fresh water, but it is susceptible to dezincification corrosion in humid or sulfur-containing environments.

Environmental Restrictions:

High lead content (0.8%-1.9%) requires careful use in scenarios subject to RoHS and other environmental regulations.

Chemical Composition

Element | Cu | Pb | Zn | Fe | Total Impurities |

Content (%) | 57.0-60.0 | 0.8-1.9 | Remainder (approx. 38%-41%) | ≤0.5 | ≤1.0 |

HPb59-1 Brass Material Properties

Physical Properties

Property Parameter | Value | Remarks |

Density | 8.5 g/cm³ | Lightweight design advantage |

Electrical Conductivity | Approx. 20% IACS | Lower than pure copper, meets general conductivity requirements |

Thermal Conductivity | 105-110 W/(m·K) | Suitable for heat dissipation components |

Coefficient of Linear Expansion | 20.5×10⁻⁶/°C (20-300°C) | Good thermal stability |

Melting Point | 900-930°C | General casting fluidity |

Mechanical Properties

Property Parameter | Value | Test Conditions |

Tensile Strength (σb) | 380-550 MPa | Varies significantly with processing state (hot working/annealed) |

Elongation (δ10) | ≥10% (annealed) | Plasticity significantly reduced(Y) |

Hardness (HB) | 75-130 | Higher hardness(Y) |

Cutting Performance Rating | 85% (with free-machining steel as 100%) | High efficiency for automatic machine tool processing |

Common Product Forms and Specifications

Product Form | Specification Range | Standard/State |

Bar | Diameter 5-120mm, Length 1-6m | GB/T 4423, Hot Rolling (R) or Annealed (M) |

Wire | Diameter 1.0-12.7mm | GB/T 14954, Hard (Y) |

Plate | Thickness 5-60mm, Width 200-600mm | hot rolled plate (R) |

Irregular shape | Hexagonal bars, square bars, etc. | Custom-made as per requirements |

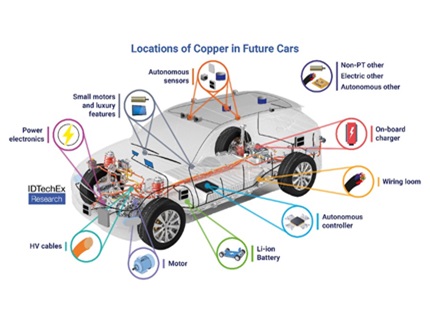

Core Application Areas

Valve Parts: Valve cores, valve stems (requiring high wear resistance and machining precision).

Hardware Parts: Locks, faucet bodies, gear blanks.

Connectors: Plugs, sockets (requiring precision turning).

Fuel System Parts: Nozzles, fuel pipe connectors (requiring pressure resistance and machining adaptability).

Precision Parts: Watch gears, instrument screws (requiring high surface finish).

Processing Considerations

Cold heading and cold stamping may cause cracking, only suitable for hot working or cutting operations.

After hot working, anneal at 500-600°C to eliminate internal stress.

It is recommended to use sulfur- or chlorine-containing cutting fluids to improve surface quality.

Lead-containing materials must comply with RoHS exemption clauses or be used in specific industrial scenarios.

Frequently Asked Questions

Q: What is the difference between HPb59-1 and HPb63-3?

A: HPb63-3 has a higher copper content (62%-65%) and a higher lead content (2.4%-3.0%), offering superior cutting performance but at a higher cost. Brass HPb59-1 offers better cost-performance ratio, suitable for general-purpose parts.

Q: Is it suitable for seawater environments?

A: It is not recommended for direct use in seawater; the corrosion rate is approximately 0.15 mm/year, and nickel plating or a protective coating is required.

Q: How to avoid lead contamination during processing?

A: Equip with dust extraction devices during processing, and dispose of waste as hazardous waste to avoid human or environmental contact.

Standard References

Chemical Composition and Processing Specifications: GB/T 5231-2012, GB/T 4423-2007 (Bars).

International Standards: ASTM B124 (American standard for bars), JIS H3250 (Japanese Standard).

Note: The above data is compiled from national standards and industry technical documents; actual parameters may vary slightly due to differences in production processes. For specific parameters, refer to the supplier's test report.

English

English 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文