Designation and Standards

Standard Designation: QSn6.5-0.1 (Phosphor Bronze)

Implementing Standards: GB/T 5231-2012 (Wrought Copper and Copper Alloys), GB/T 4423-2007 (Bars)

International Equivalent Grades: ASTM C51900, EN CuSn6 (EN 12163), JIS C5191

Material Category: Copper-Tin-Phosphorus Alloy (Cu-Sn-P), Tin content 6.0%-7.0%, Phosphorus content 0.1%-0.25%, Copper balance.

Product Characteristics

Superb Elasticity and Fatigue Resistance:

Elastic limit ≥450 MPa, fatigue life 3-5 times that of common brass, suitable for high-frequency elastic components.

Excellent Wear and Corrosion Resistance:

Corrosion-resistant to atmosphere, seawater, and weak acids (corrosion rate ≤0.005 mm/a), wear resistance superior to QSn4-0.3.

Precision Machining Adaptability:

Excellent cold/hot working performance, supports stamping, drawing, welding; however, annealing is required after cold working to restore plasticity.

Balanced Electrical and Thermal Conductivity:

Electrical conductivity approximately 13% IACS, thermal conductivity 60-70 W/(m·K), suitable for applications requiring both conductivity and wear resistance.

Chemical Composition

Element | Cu | Sn | P | Pb | Total Impurities |

Content (%) | Remainder (≥92.75%) | 6.0-7.0 | 0.1-0.25 | ≤0.02 | ≤0.1 |

Physical Properties

Property | Value | Remarks |

Density | 8.8-8.9 g/cm³ | High density, suitable for precision components |

Electrical Conductivity | Approximately 13% IACS | Lower than pure copper, but meets industrial elasticity requirements |

Thermal Conductivity | 50-60 W/(m·K) | Moderate heat dissipation ability |

Coefficient of Linear Expansion | 17.6×10⁻⁶/°C (20-200°C) | Excellent thermal stability |

Melting Point | 995-1020°C | Moderate casting fluidity |

Mechanical Properties

Property | Value | Test Conditions |

Tensile Strength (σb) | 400-750 MPa | M ≥400 MPa, Y ≥750 MPa |

Elongation (δ10) | 3%-65% | Up to 65% (M) |

Hardness (HV) | 90-240 | Significant increase in hardness (Y) |

Elastic Modulus | ≥115 GPa | Core indicator for spring applications |

Annealing Temperature | 650-750°C (stress relief) | Recommended annealing process |

Common Product Forms and Specifications

Product Form | Specification Range | Typical Applications |

Strip | Thickness 0.05-2.0mm, Width ≤600mm | Precision spring sheets, relay contacts |

Wire | Diameter 0.05-10.0mm | Medical equipment springs, electronic leads |

Bar | Diameter 3-150mm, Length 2000-6000mm | Bearings, gears, wear-resistant bushings |

Foil | Thickness 0.01-0.1mm | Micro sensor springs |

Core Application Fields

High-end Electronics:

5G communication equipment: RF connector springs, shielding covers (high elasticity required).

Semiconductor test probes: Wear-resistant, long-life contact components.

Precision Machinery:

Aerospace: Gyroscope springs, hydraulic valve plates (fatigue resistance).

Medical instruments: Endoscope springs, surgical clamp joints (biocompatibility requirements).

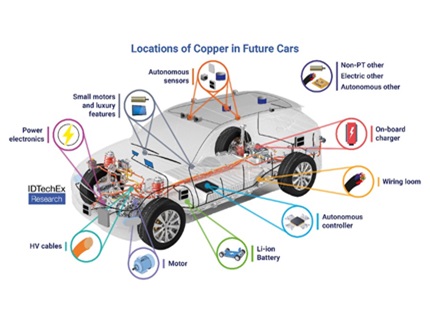

Automotive Industry:

High-pressure fuel injection systems: Precision springs, sealing rings (corrosion resistance and high-pressure suitability).

Marine Engineering:

Deep-sea equipment: Corrosion-resistant seawater valves, sensor components.

Processing Considerations

Annealing Control:

Cold working deformation exceeding 30% requires annealing at 650-750°C to prevent grain coarsening.

Welding Process:

Prefer laser welding or electron beam welding to reduce embrittlement in the heat-affected zone.

Surface Treatment:

Gold/silver plating to improve conductivity, or PVD coating to enhance wear resistance.

Cutting Parameters:

Cutting speed ≤50 m/min, use oily cooling fluids to prevent tool adhesion.

Frequently Asked Questions

Q: What is the difference between QSn6.5-0.1 and QSn4-0.3?

A: QSn6.5-0.1 has a higher tin content (6%-7% vs. 4%), offering superior elasticity and wear resistance, but at a higher cost, making it suitable for high-precision applications.

Q: Is it suitable for high-temperature environments?

A: Long-term use temperature ≤150°C, short-term can withstand up to 250°C, but will significantly annealed above 300°C.

Q: How can cold processing cracking be avoided?

A: Control single deformation amount (≤30%), and insert annealing steps between multiple processing; avoid excessive acid pickling to prevent hydrogen embrittlement.

Standards References

Chemical Composition and Processing Specifications: GB/T 5231-2012, GB/T 4423-2007 (Bars).

International Standards: ASTM B103 (American standard for strips), EN 12163 (European Standard), JIS H3270 (Japanese standard for bars).

Note: The data above is based on national standards and industry technical documents. Actual performance may vary slightly due to production processes, and specific values should be verified with the supplier's test report.

English

English 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文