Designation and Standards

International Common Grades:

China: TP1 (GB/T 5231-2012)

America: C12100 (ASTM B88)

Japan: C1201 (JIS H3300)

European Union: CU-ETP/CW023A (EN 1172)

International Standard: CU-DLP (ISO 1337)

Product Features

Deoxidized Copper Characteristics: Contains trace phosphorus (0.005-0.012%), excellent deoxidation ability, and significantly better welding performance compared to common copper.

High Conductivity/Thermal Conductivity: Conductivity ≥ 90% IACS, Thermal conductivity ≥ 350 W/(m·K), suitable for high-performance electrical and thermal conductivity applications.

Corrosion Resistance: Excellent resistance to high-temperature oxidation and steam corrosion, suitable for chemical pipelines, condensers, and other humid/high-temperature environments.

Workability:

Excellent cold working properties, can be made into thin-walled tubes or complex shapes.

For hot working, temperature control is required (annealing temperature: 500-700°C) to avoid grain coarsening.

Hydrogen Embrittlement Resistance: Phosphorus elements inhibit hydrogen penetration, reducing the risk of "hydrogen embrittlement" and enabling processing in reducing atmospheres.

Common Product Forms and Dimensions

Product Form | Dimension Range | Applicable Standard |

Tube | Outer Diameter: 5-219mm, Wall Thickness: 0.5-10mm | GB/T 1527-2017 |

Bar | Diameter: 10-150mm | GB/T 1528-2019 |

Plate/Strip | Thickness: 0.3-10mm, Width ≤1000mm | GB/T 2059-2017 |

Wire | Diameter: 0.5-20mm | GB/T 14953-2017 |

Irregular shape | Custom dimensions based on customer drawings | Agreement Technical Conditions |

Note: Tubes are the main form and are widely used in refrigeration and heat exchange fields. |

Chemical Composition (GB/T 5231-2012)

Component | Cu+Ag | Pb | Sb | Bi | P | Fe | S | Other Impurities |

Content (%) | ≥99.90 | ≤0.005 | ≤0.002 | ≤0.001 | 0.005-0.012 | ≤0.005 | ≤0.005 | ≤0.05 |

Note: The phosphorus content is low, offering superior conductivity compared to TP2, but must be strictly controlled to below 0.012%.

Physical Properties

Property | Value |

Density | 8.9 g/cm³ |

Conductivity | 90-93% IACS |

Thermal Conductivity | 350 W/(m·K) |

Thermal Expansion Coefficient | 17.7×10⁻⁶/K |

Elastic Modulus | 132 GPa |

Melting Point | 1083°C |

Data source: GB/T 5231-2012 and industry common standards. |

|

Mechanical Properties

State | Tensile Strength (MPa) | Elongation (%) | Vickers Hardness (HV) |

Hard (Y) | ≥275 | ≥5 | 80-110 |

Annealed (M) | ≥200 | ≥40 | 50-70 |

Note: Y is suitable for high-strength pressure-bearing applications, while M is suitable for deep stamping and complex forming. |

Core Advantages

Excellent Welding Performance: The phosphorus deoxidation process reduces oxidation risks, supporting high-precision processes such as flame welding and induction welding.

High Purity and Environmental Friendliness: Low impurity content, recyclable, and compliant with environmental requirements.

Balanced Performance: Combines excellent conductivity, thermal conductivity, and corrosion resistance, adaptable to multiple field requirements.

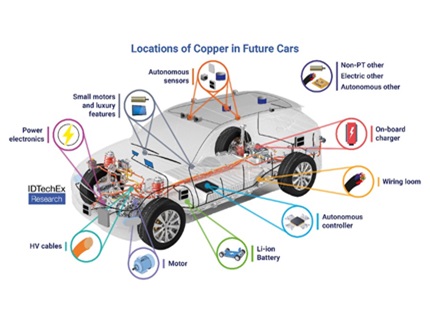

Product Applications

Refrigeration Industry: Air conditioning condenser tubes, refrigerator evaporators.

Chemical Equipment: Corrosion-resistant pipelines, reactor linings.

Electrical Electronics: Cable conductors, heat sink substrates.

Architectural Decoration: Art sculptures, weather-resistant roofing materials.

Processing Notes

Welding Process: Prefer phosphorus-containing solder (e.g., BCuP series), preheat to 200-300°C before welding, and control sources of oxygen and hydrogen.

Annealing Control: Soft material annealing temperature ≤ 700°C, avoid repeated annealing to prevent grain coarsening.

Surface Treatment: After acid pickling, thoroughly rinse to prevent residual phosphides from causing corrosion.

Frequently Asked Questions

Q: What is the main difference between TP1 and TP2?

A: TP1 has lower phosphorus content (0.005-0.012% vs. 0.015-0.040% in TP2), offering higher conductivity, but its welding performance is slightly inferior to TP2.

Q: Is TP1 suitable for drinking water pipelines?

A: It must comply with GB/T 18033-2017 standards and pass migration testing for lead, arsenic, and other elements.

Q: How should TP1 be treated after cold working?

A: After cold work hardening, it should be annealed to restore ductility, with a recommended temperature of 500-600°C.

Standards Reference

Chemical Composition: GB/T 5231-2012

Tube/Bar: GB/T 1527-2017, GB/T 1528-2019

Welding Standards: GB/T 985.1-2008

Disclaimer: The technical parameters in this manual are based on national standards and industry common data. Specific applications should be considered in conjunction with operational conditions and third-party testing reports. For complete technical documentation, please contact the supplier or refer to the relevant standard documents.

English

English 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文