- Home

-

Products

By Types

By Application

Leaded Brass Rod Lead-free Brass Rod Ordinary Brass Rod Machining Friendly Brass Rod Tin Zinc Lead Bronze Rod Anti-dezincation Brass Rod Chromium Zirconium Copper Bronze Rod Profile Rod Precision Extrusion Rod Copper Rod Brass Round Wire (Copper Alloy) Brass Flat Wire (Copper Alloy) Tellurium Copper Rod Low-Silicon Bronze B -

Code

Cu-OFE Copper Cu-HCP Copper Cu-PHC Copper Cu-ETP Copper Cu-DHP Copper Cu-DLP Brass CuZn5 Brass CuZn10 Brass CuZn15 Brass CuZn20 Brass CuZn30 Brass CuZn33 Copper CuZn36 Copper CuZn37 Copper CuZn40 Copper CuSn4 Phosphor Bronze CuSn5 Phosphor Bronze CuSn6 Phosphor Bronze CuSn8 Phosphor Bronze CuNi12Zn24 Nickel Silver CuZn20Al2As Copper CuZn28Sn1As Copper CuZn31Si1 Copper CuZn35Pb1 Copper CuZn35Pb2 Copper CuZn36Pb3 Copper CuZn38Pb2 Copper CuZn39Pb2 Copper CuZn39Pb3 Copper CuZn40Pb2 CopperC10100 Copper C10300 Copper C11000 Copper C12000 Copper C12200 Copper C21000 Copper C22000 Bronze C23000 Brass C24000 Brass C26000 Brass C26800 Brass C27000 Brass C27200 Brass C28000 Brass C34000 Brass C34200 Brass C35000 Brass C36000 Brass C37700 Brass C38000 Brass C38500 Brass C44300 Brass C51000 Bronze C51100 Bronze C51900 Bronze C52100 Bronze C68700 Brass C68800 Brass C70600 Copper C71500 Copper C75700 Copper C76400 Copper C77000 CopperC1011 Copper C1100 Copper C1201 Copper C1220 Copper C2600 Brass C2680 Brass C2700 Brass C2720 Brass C2100 Copper C2200 Copper C2300 Copper C2400 Copper C3501 Brass C3601 Brass C3603 Brass C3712 Brass C3771 Brass C4430 Brass C5102 Bronze C5111 Bronze C5191 Bronze C5210 Bronze C6870 Brass C7060 Copper C7150 Copper C7521 Copper C7701 CopperCuNi10Fe1Mn Copper CuNi12Zn24 Copper CuNi18Zn20 Copper CuNi18Zn27 Copper CuNi30Mn1Fe Copper CuZn5 Brass CuZn10 Brass CuZn15 Brass CuZn20 Brass CuZn20Al2 Copper CuZn28Sn1 Brass CuZn30 Brass CuZn31Si1 Copper CuZn33 Brass CuZn36 Brass CuZn36Pb1.5 Brass CuZn36Pb3 Brass CuZn37 Brass CuZn38Pb1.5 Brass CuZn39Pb2 Brass CuZn39Pb3 Brass CuZn40 Brass CuZn40Pb2 Brass E-Cu58 Copper OF-Cu Copper SE-Cu Copper SF-Cu Copper SW-Cu Copper

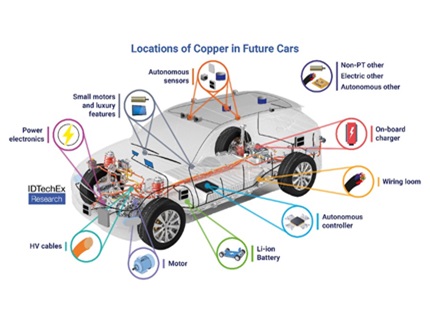

- Application

- About Us

- Resource

- Contact Us

English

English 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文