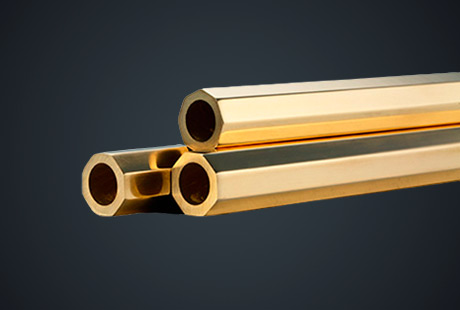

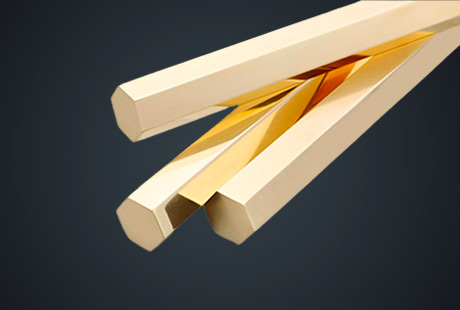

Features of Inner Grooved Copper Tubes

Inner Grooved Copper Tubes are copper tubes with excellent performance, featuring a spiral threaded structure on the inner surface. Compared to smooth copper tubes, Inner Grooved Copper Tubes have the following advantages:

Increased Heat Transfer Area

The teeth of the internally threaded tube can increase the surface area inside the pipe, thereby increasing the heat transfer area and improving heat transfer efficiency. Generally, internally threaded tubes can increase the surface area by 20% to 25% compared to smooth tubes of the same diameter.

Increased Turbulence

The teeth of the internally threaded tube can increase the turbulence inside the pipe, producing a spiral flow along the inner wall of the tube. This increases the relative velocity between the fluid and the tube wall, causing more vigorous fluid motion and reducing the thickness of the laminar sublayer. The centrifugal force generated by the spiral flow can fling droplets contained in the steam back to the wall, delaying the onset of dry-out, thereby enhancing the heat transfer between the fluid and the tube wall.

Destruction of Thermal Boundary Layer

The teeth of the internally threaded tube can disrupt the thermal boundary layer, where the main effect of the separated flow is to agitate the boundary layer, making the fluid there tend to mix uniformly and come into easier contact with the tube wall, thus improving heat transfer efficiency.

Increased Fluid Mixing

The teeth of the internally threaded tube can increase the mixing of the fluid, making it more evenly distributed inside the pipe, thereby enhancing heat transfer efficiency. In essence, using an internally threaded structure causes fluid to rotate, which agitates the fluid and delays the formation of a vapor film during the first kind of heat transfer degradation, preventing film boiling. During the second kind of heat transfer degradation, the spiral flow can fling droplets back to the wall, delaying dry-out. Internally threaded tubes can improve the heat transfer coefficient inside the tube, increase critical heat flux density, and delay the occurrence of heat transfer degradation. Even when heat transfer degradation occurs, it can improve heat transfer characteristics and effectively lower the wall temperature.

Increased heat transfer area, enhancing heat conduction efficiency, generally increases the inner surface area by 20%-25% compared to smooth tubes of the same diameter.

Optimizes fluid flow, making heat transfer more uniform and reducing temperature gradients.

Reduces the connections between copper tubes and simplifies pipeline layout, reducing costs.

Application of Inner Grooved Copper Tubes in Air Conditioning

In addition to being widely used in general fields, the Inner Grooved Copper Tube is also essential materials in the air conditioning and refrigeration industry. They are primarily used in the following areas:

Indoor Unit Copper Tubes

Inner Grooved Copper Tubes are widely used in the copper tubes of air conditioning indoor units, mainly for refrigerant heat transfer. Due to the excellent performance of Inner Grooved Copper Tubes, the cooling efficiency and heat exchange efficiency of air conditioning indoor units are significantly improved.

Outdoor Unit Copper Tubes

The cooling effect of the outdoor unit is influenced by various factors, such as air dryness and environmental temperature. To better adapt to different cooling needs, Inner Grooved Copper Tubes are also widely used in the copper tubes of air conditioning outdoor units. Compared to ordinary copper tubes, Inner Grooved Copper Tubes can increase the contact area between the refrigerant and the air, enhancing heat exchange efficiency and thereby improving the cooling capacity of the outdoor unit.

Other Air Conditioning Equipment

In other air conditioning equipment, the Inner Grooved Copper Tubes in AC is also widely used, such as fan coil units, chilled water units, and air source heat pumps. The reason for their widespread application is that the excellent performance of internally threaded copper can meet the high requirements of these devices.

Advantages of Internally Threaded Copper

Inner Grooved Copper Tubes have the following advantages:

In summary, Inner Grooved Copper Tubes are an excellent copper tubing material widely used in the air conditioning industry. Their widespread application is due to their superior performance, which can both improve the cooling efficiency of air conditioning products and reduce system costs, providing air conditioning products with better cost-performance.

As a leading manufacturer of Inner Grooved Copper Tubes, Jintian professionally produces high-quality copper tubes with a series of grooves or ridges on the inner surface. Our products are made from the finest materials and undergo rigorous testing to ensure they meet the highest standards of excellence. Jintian is one of the most reputable internally threaded copper tube manufacturers in China, known for producing high-quality products and competitive prices. With years of industry experience, Jintian has become a trusted supplier of internally threaded tubes for customers worldwide.

English

English 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文