What is a Busbar?

In the realm of electrical power distribution, a busbar is a robust strip or bar made of copper or aluminum that serves as a conductor of electricity within switchboards, distribution boards, substations, or other electrical apparatus. Busbars are designed to handle very high currents or to distribute current to multiple devices within switchgear or equipment.

For instance, in a household circuit breaker panel, busbars are located behind the back panel and feature protruding connection points for attaching multiple branch circuit breakers. In an aluminum smelting facility, extremely large busbars are employed to carry tens of thousands of amperes to the electrochemical cells that extract aluminum from alumina ore.

For extremely high currents, where providing circuit protection is challenging, an isolated-phase bus is utilized. In this setup, each phase of the circuit is housed in a separate grounded metal enclosure. This design minimizes the risk of faults, limiting them to phase-to-ground faults unless a catastrophic physical event occurs. Such bus systems can be rated for up to 50,000 amperes and can handle voltages reaching hundreds of kilovolts under normal operating conditions.

What is the Function of Switchgear?

Switchgear refers to a collection of circuit-protecting devices housed within a metal enclosure. These devices typically include switches, fuses, and circuit breakers.

The primary role of switchgear is to manage and regulate electrical circuits in power systems that require substantial power, such as those used by electrical utilities. Essentially, switchgear systems facilitate the distribution of power, balance electrical loads, and ensure the safe flow of electrical current.

Switchgear systems are categorized based on voltage levels into low voltage, medium voltage, and high voltage.

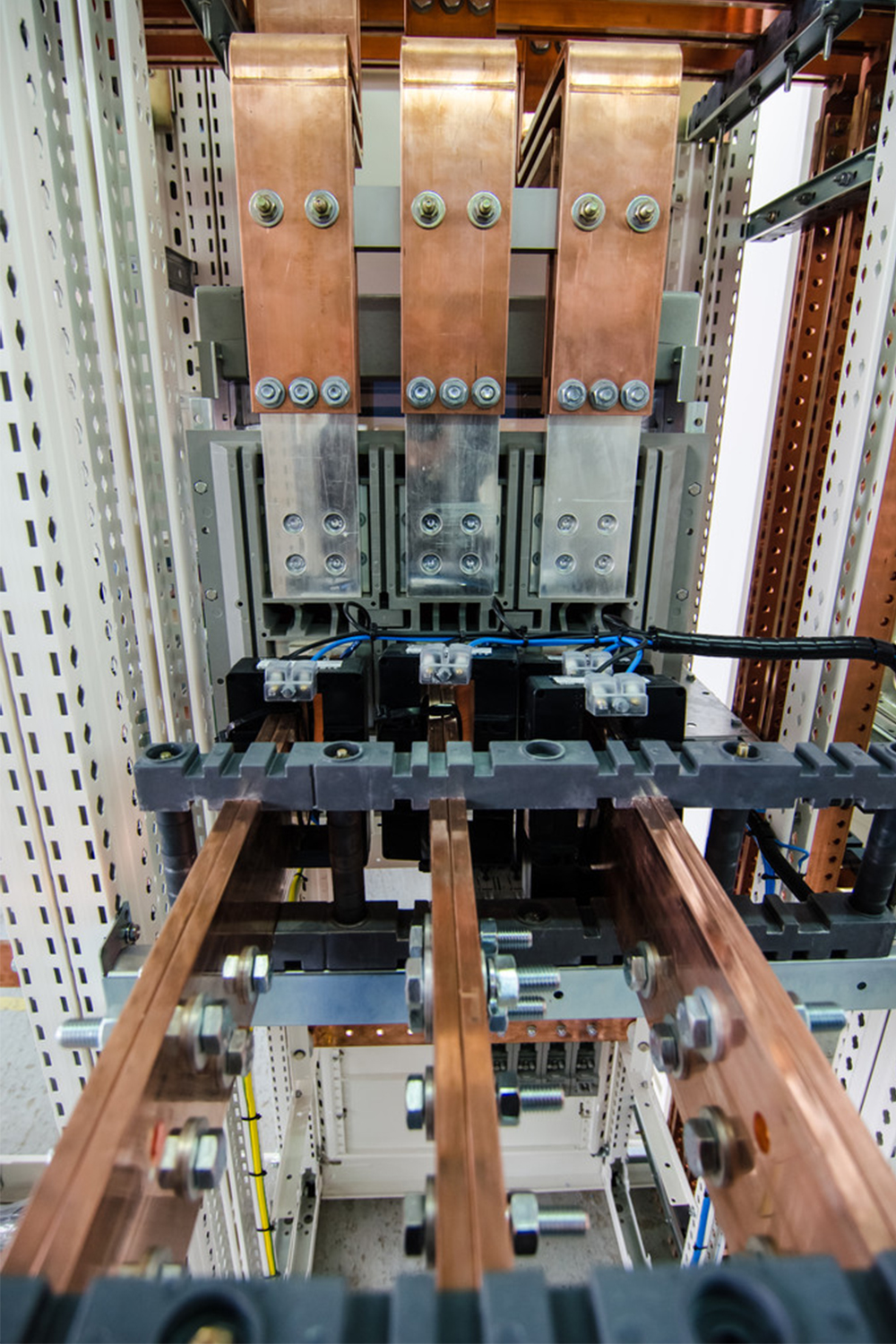

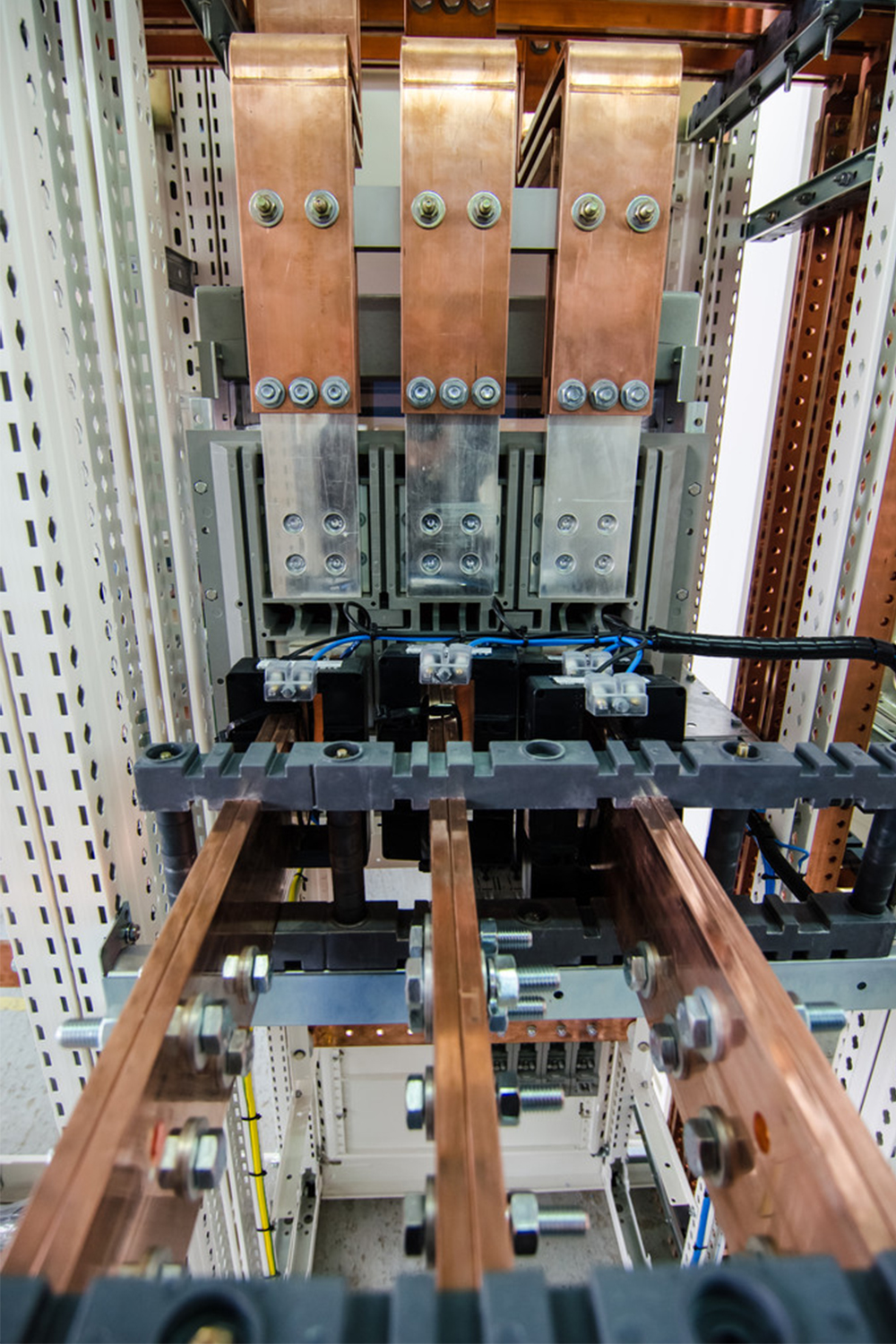

What Role Does Bus Bar Play in Switchgear?

Enclosed within the switchgear, the busbar acts as a conductor that channels electric current to various circuits within the system. Compared to conventional cabling, busbars offer enhanced safety and convenience. Due to their durability and efficiency, busbars require less frequent replacement than traditional cabling systems.

Why Choose Copper Busbar ?

Copper has established itself as the premier material for busbars over the centuries, and there are compelling reasons for this choice. One of the most notable benefits of copper is its exceptional electrical conductivity. This ensures that minimal energy is lost as heat when electricity flows through a copper busbar, resulting in efficient power transmission. While silver has slightly higher conductivity, copper’s cost-effectiveness makes it the preferred option for industrial applications.

Moreover, copper naturally resists corrosion, a critical feature in environments prone to moisture or chemical exposure. This resistance helps maintain the busbar’s integrity, preventing premature degradation that could jeopardize the safety and efficiency of the entire electrical system.

Additionally, copper’s excellent thermal properties are vital for managing the heat generated during electrical operations. As electricity passes through the busbar, resistance generates heat. Copper’s superior thermal conductivity allows it to dissipate this heat effectively, preventing overheating and potential damage.

The Importance of Busbar Shape

The shapes of copper busbars are not just about aesthetics; they play a crucial role in determining overall performance and efficiency. The shape of a busbar directly impacts its surface area, with a larger surface area allowing for more effective heat dissipation. This is particularly important during high current loads to ensure the busbar remains within operational temperature limits.

Additionally, the shape of the busbar affects its electrical resistance. For instance, a flat bar may have lower resistance than a rounded one of the same volume due to its larger surface area. This difference can significantly influence the efficiency of power distribution, especially in systems where even minor changes in resistance can lead to substantial energy losses.

The shape also influences the busbar’s current-carrying capacity. Certain designs can handle more current without overheating, making them more suitable for high-demand applications. For example, a rectangular busbar might be preferred in high-current systems, while a rounded one might be chosen for more compact installations.

Flat Busbars

Flat busbars are among the most common types of copper busbars. They are easy to install and offer a high surface area, which is excellent for heat dissipation. This shape is often used in electrical panels, switchgear, and other applications. Their design allows for straightforward connections and can be easily customized in various lengths and widths.

Round Busbars

Round busbars are solid or hollow cylinders of copper. While they offer less surface area for heat dissipation compared to flat busbars, they can carry high currents. These are ideal for applications requiring high mechanical strength. Their cylindrical shape also allows for easy rotation and flexible installation options.

Custom-Shaped Busbars

Sometimes, standard shapes are not sufficient. In such cases, custom-shaped busbars are the solution. These copper busbars are designed to fit unique applications and are generally made-to-order. They can include complex bends, multiple layers, or special coatings to meet the needs of specialized projects.

Applications of Copper Busbars in Electrical Panels and Switchgear

Power Distribution

Copper busbars are commonly used in power distribution systems within electrical panels and switchgear. They serve as the main conductors that distribute electrical power from the source to various circuits and devices. Their high conductivity and current carrying capacity make them ideal for ensuring efficient and reliable power distribution.

Grounding and Bonding

In electrical panels and switchgear, copper busbars are often used for grounding and bonding purposes. They provide a low-resistance path to ground, ensuring the safe dissipation of fault currents and preventing electrical shock hazards. Proper grounding and bonding are essential for the safety and stability of electrical systems.

Connection Points

Copper busbars serve as connection points for various electrical components within panels and switchgear. They provide a secure and stable platform for connecting circuit breakers, fuses, relays, and other devices. The use of copper busbars ensures reliable electrical connections and minimizes the risk of loose or faulty connections.

Heat Dissipation

Copper busbars play a crucial role in heat dissipation within electrical panels and switchgear. Their high thermal conductivity allows them to effectively dissipate heat generated by electrical currents, preventing overheating and ensuring the safe operation of the system. Proper heat dissipation is essential for maintaining the longevity and performance of electrical components.

Installation Practices for Copper Busbars

Proper Handling and Storage

Proper handling and storage of copper busbars are crucial to prevent damage and ensure their performance. Busbars should be stored in a clean, dry environment to avoid corrosion and contamination. During handling, care should be taken to avoid bending, scratching, or denting the busbars, as these can compromise their electrical and mechanical properties.

Secure Mounting

Copper busbars must be securely mounted within electrical panels and switchgear to ensure stable and reliable connections. Mounting brackets, clamps, or supports should be used to fix the busbars in place and prevent movement or vibration. Proper mounting also helps to maintain the alignment and spacing of the busbars, reducing the risk of short circuits and electrical faults.

Connection Techniques

The connections between copper busbars and other electrical components should be made using appropriate techniques to ensure low-resistance and reliable joints. Common connection methods include bolted joints, welded joints, and crimped connections. It is important to use the correct tools and materials for each connection method to achieve optimal results.

Inspection and Testing

After installation, copper busbars should be thoroughly inspected and tested to verify their performance and safety. Visual inspections can help identify any physical damage, loose connections, or improper insulation. Electrical tests, such as continuity tests and insulation resistance tests, can be conducted to ensure the integrity of the busbar system.

Maintenance of Copper Busbars

Routine Inspections

Regular inspections are essential for maintaining the performance and safety of copper busbars in electrical panels and switchgear. Inspections should include checking for signs of corrosion, wear, or damage, as well as verifying the tightness of connections and the condition of insulation. Any issues identified during inspections should be addressed promptly to prevent further problems.

Cleaning and Corrosion Prevention

Keeping copper busbars clean and free from corrosion is important for ensuring their longevity and performance. Busbars should be cleaned periodically using appropriate cleaning agents and methods to remove dirt, dust, and oxidation. Additionally, anti-corrosion treatments or coatings can be applied to protect the busbars from environmental factors.

Tightening Connections

Over time, connections between copper busbars and other components may loosen due to thermal expansion and contraction or mechanical vibrations. Regularly checking and tightening connections can help maintain low-resistance joints and prevent electrical faults. It is important to use the correct torque specifications when tightening connections to avoid over-tightening or damaging the busbars.

Monitoring and Testing

Continuous monitoring and periodic testing of copper busbars can help detect potential issues before they become critical. Monitoring systems can track parameters such as temperature, current, and voltage to identify abnormal conditions. Periodic electrical tests, such as thermal imaging and resistance measurements, can provide valuable insights into the health of the busbar system.

JT Copper: A Leading Manufacturer of Copper Busbars

When it comes to high-quality copper busbars for electrical panels and switchgear, JT Copper is a trusted name in the industry. With years of experience and a commitment to excellence, JT Copper offers a wide range of copper busbars that meet the highest standards of performance and reliability.

Why Choose JT Copper?

Quality Assurance: JT Copper adheres to strict quality control measures to ensure that every busbar meets the required specifications and standards. The products undergo rigorous testing and inspection to guarantee superior performance and durability.

Customization: JT Copper offers customized solutions to meet the unique needs of their customers. Whether you need specific dimensions, shapes, or configurations, JT Copper can provide tailored busbars that fit your requirements.

Expertise: With a team of experienced engineers and technicians, JT Copper has the expertise to assist with design, fabrication, and installation of copper busbars. The technical support ensures that you get the best solutions for your electrical systems.

Competitive Pricing: JT Copper offers competitive pricing without compromising on quality. The cost-effective solutions provide excellent value for money, making them a preferred choice for many industries.

For more information about JT Copper and the range of copper busbars, visit the website at www.jtcopper.com or contact our sales team at service@jtgroup.com.cn. Whether you need standard busbars or customized solutions, JT Copper is your reliable partner for all your copper busbar needs.

In conclusion, copper busbars play a vital role in the efficient and reliable operation of electrical panels and switchgear. Their superior conductivity, durability, and versatility make them the preferred choice for a wide range of applications. By understanding the benefits, applications, design considerations, installation practices, and maintenance of copper busbars, you can ensure the optimal performance and safety of your electrical systems. And with JT Copper as your trusted manufacturer, you can be confident in the quality and reliability of your copper busbar solutions.

English

English 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文