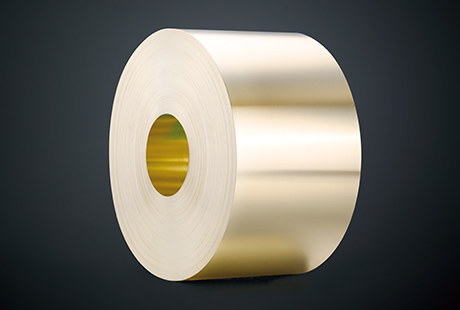

Copper is widely used in medical gas delivery systems due to its excellent thermal conductivity, corrosion resistance, and low reactivity with gases. Copper pipes are commonly used in medical gas and vacuum systems for their durability and reliability. In this article, we will explore the benefits of using copper pipes in medical gas and vacuum systems and their applications.

What is Copper Pipe for Medical Gas and Vacuum?

Copper pipes for medical gas and vacuum systems are specifically designed and manufactured for the medical industry. Copper medical pipes are made to meet stringent standards to ensure that they are safe and reliable for use in medical gas delivery systems. Copper pipes used in medical gas and vacuum systems are typically made from high-quality, medical-grade copper that is free from impurities and contaminants.

Copper Tubing for Oxygen Service

These copper pipes are specifically designed for the safe distribution of oxygen in medical, industrial, and laboratory applications. As Oxygen is a highly reactive gas, and using the correct type of copper tubing ensures that the system remains safe, reliable, and resistant to contamination or degradation over time. The oxygen copper pipe must be specifically designed to prevent any contamination or reactions that could occur when oxygen is exposed to certain materials.

Benefits of Copper Pipe for Medical

Ensures Safety: Copper pipes for medical gas and vacuum systems are manufactured to meet stringent standards, ensuring that they are safe for use in medical environments. The high-quality, medical-grade copper used in these pipes is free from impurities and contaminants, reducing the risk of gas contamination and ensuring that patients and medical professionals remain safe.

High Durability: Copper pipes are highly durable and resistant to corrosion, ensuring that they remain reliable and safe for use in medical gas delivery systems for years to come. Copper pipes are less likely to corrode or degrade over time, reducing the need for frequent replacements and repairs.

Excellent Thermal Conductivity: Copper pipes have excellent thermal conductivity, making them ideal for use in medical gas and vacuum systems. The high thermal conductivity of copper ensures that gases are delivered at the correct temperature, improving the efficiency of medical gas delivery systems.

Low Reactivity: Copper pipe fittings for gas, like ac copper pipe fittings, have low reactivity with gases, reducing the risk of gas contamination and ensuring that medical gases remain pure and uncontaminated.

Applications of Copper Pipe for Medical Gas

Some of the most common applications of copper pipe in medical gas delivery systems include:

Hospitals and Clinics: Copper pipes are commonly used in hospitals and clinics for the delivery of medical gases and vacuum. Medical gases, such as oxygen and nitrous oxide, are essential for patient care in these environments, and copper pipes ensure that these gases are delivered safely and efficiently.

Dental Offices: Copper pipes are also used in dental offices for the delivery of medical gases and vacuum. Dental offices require the delivery of medical gases, such as oxygen and nitrous oxide, to provide patients with comfortable and safe care.

Research Facilities: Copper pipes are also used in research facilities for the delivery of medical gases and vacuum. Research facilities require a reliable and efficient delivery of medical gases to ensure accurate results and safe experimentation.

Installation of Medical Gas Copper Pipes and Fittings

Cutting and bending: Use a pipe cutter to cut the copper tubing to the required lengths. Ensure the bends are smooth and uniform to avoid kinks, which could restrict gas flow.

Deburring: After cutting, carefully deburr the edges of the tubing to remove any sharp edges or debris that could cause leaks or damage to the fittings.

Brazing: When joining medical gas copper piping, brazing is the most common and reliable method. Apply flux to the pipe and fitting areas where the joint will be made. Use a torch to heat the joint until the brazing rod melts and flows into the joint, creating a strong and leak-proof bond. Allow the joint to cool before inspecting it for any imperfections.

Compression fittings: If using compression fittings, insert the copper tube into the fitting, and tighten the nut to compress the ferrule, which forms a seal.

Flare fittings: For flare fittings, the end of the copper pipe is flared into a conical shape to fit into a matching fitting. Ensure a tight, leak-proof connection.

Test for leaks: Once the gas copper pipe line is installed, conduct a pressure test to check for any leaks in the system. Use compressed air or nitrogen for the test, as these gases are non-reactive and safe to use.

Visual inspection: Perform a thorough visual inspection to ensure that all joints, fittings, and supports are correctly installed and secure.

Clean the system again: If the pipes were cleaned initially, ensure that the system is flushed again before use to remove any contaminants from the installation process.

Maintenance and Care for Copper Pipe for Medical

Copper pipes for medical gas and vacuum systems require proper maintenance and care to ensure their longevity and reliability. Regular inspections and maintenance of medical gas copper tube can help to prevent potential issues before they become major problems.

One of the most important steps in maintaining medical copper pipes is to ensure that they are kept clean and free from debris. Any debris or buildup on the internal surface of the pipe can interfere with the flow of gases, reducing the efficiency and performance of the system.

Additionally, it is important to ensure that the medical gases delivered through the system are of the highest quality and free from contaminants. Regular testing and analysis can help to identify any potential issues with the gases, ensuring that they remain safe and free from contamination.

Difference between Medical Gas Copper Pipe and Refrigeration Copper Pipe

Medical gas copper pipes and refrigeration copper pipes are both types of copper tubing, but they serve different purposes and are designed to meet distinct standards and requirements tailored to their respective applications.

| Feature | Medical Gas Copper Pipe | Refrigeration Copper Pipe |

| Application | Oxygen, nitrous oxide, medical air, etc. in healthcare settings | Refrigerants in HVAC systems, refrigeration, and air conditioning |

| Cleanliness Requirements | Must be cleaned for oxygen service to prevent contamination | Standard cleaning, no need for oxygen-specific cleaning |

| Pressure and Temperature | Low to moderate pressure, ambient temperatures | High pressure, extreme temperatures (cold and hot) |

| Material | High-purity copper, may be silver-plated or specially treated | High-quality copper, typically coated for corrosion protection |

| Joining Method | Brazing, compression fittings, with strict guidelines for safety | Brazing, soldering, compression fittings for high pressure |

| Regulations and Standards | Complies with NFPA 99, ISO 7396-1, and medical gas codes | Complies with ASHRAE standards for refrigeration systems |

Contact JT Copper

As a professional copper pipe manufacturer, JT Copper provides high-quality medical gas fittings in copper with excellent thermal and electrical conductivity. To learn more about our copper tube products:

FAQs of Medical Gas Copper Pipe

1. What is the best copper pipe for oxygen?

The best copper pipe for oxygen is typically type K or type L copper, with type K being the most commonly used for oxygen systems due to its thicker walls and added durability.

2. Can I use copper tubes for household gas?

Yes, you can use copper tubes for household gas, provided it complies with specific conditions and local building codes. Flexible copper tube is commonly used in gas distribution systems.

3. What are common types of medical gas copper fittings?

Elbows: used to change the direction of the piping system

Tees: allow branching of the pipeline

Couplings: join two pieces of pipe

Reducers: transition between different pipe sizes

Unions: allow for easy disconnection of sections of the piping system

Adapters: facilitate connections between different types of fittings or materials

4. How are medical gas copper tubes joined?

Brazing is more common for medical gas pipes system because it creates a stronger, leak-proof joint. Soldering is typically used for smaller systems and lower pressure. Compression fittings are also used for joining copper tubes. Flared Fittings are less common than brazed joints or compression fittings but are still used in certain applications.

English

English 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文